Dust Filter Shop

Bag Filter Cleaning

Proud To Serve Businesses Across the USA

Phone: 816-601-1200

Email: info@dustfiltershop.com

Filters are one of the highest costs to most industrial plants and manufacturers. Constantly replacing filters (buying new) is a thing of the past. Dust Filter Shop has developed a process to “Clean, and Recondition” dirty bag filters restoring them to new filter specifications. Dust Filter Shop’s process allows most filters to be cleaned and re-used many times. Providing YOU (our customer) with years of reliable filter life.

Bag Filter Cleaning Click on this link to see the .pdf

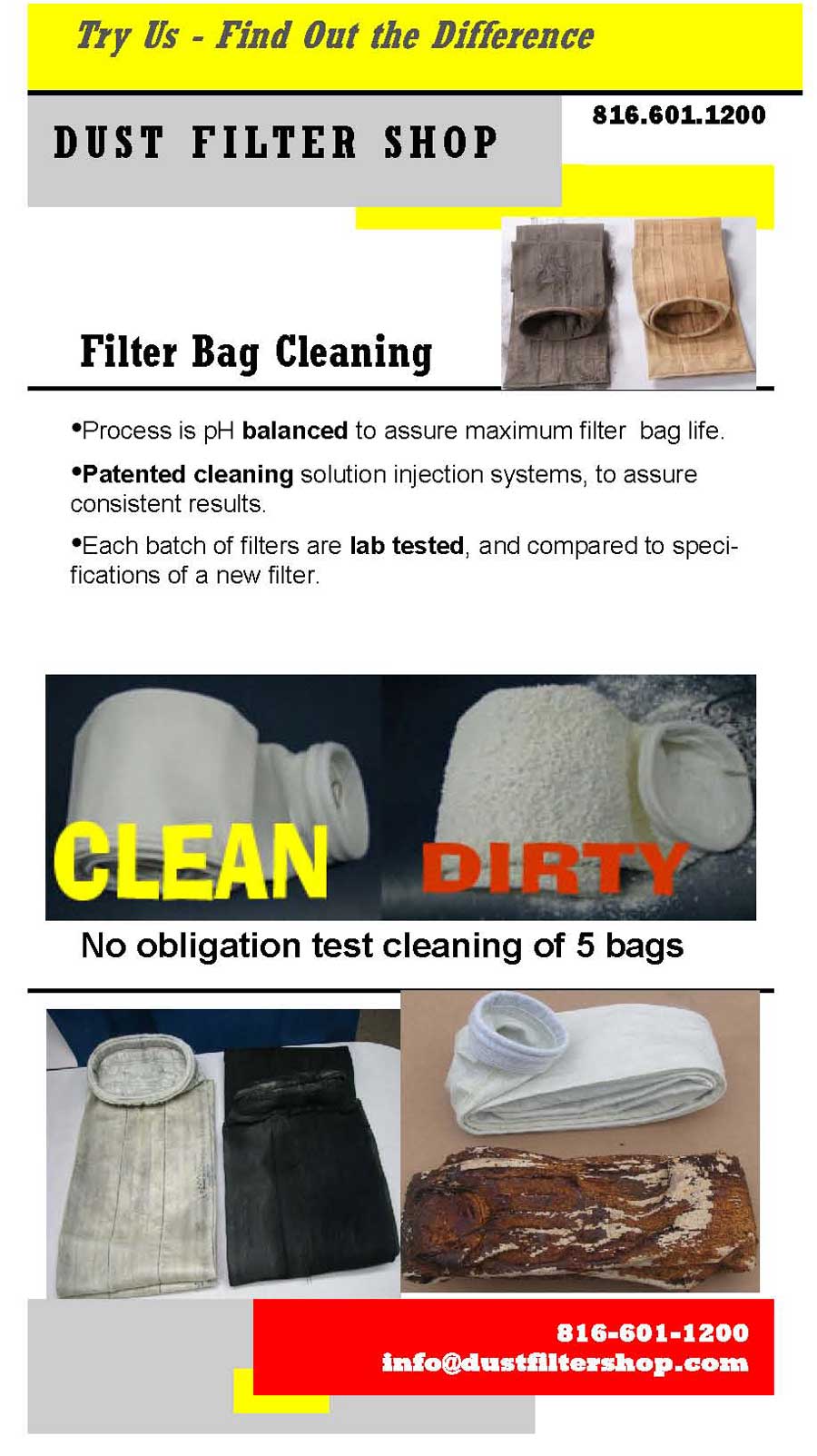

Filter Bag Cleaning

Bag Filters have been around for over a hundred years. Filter bag medias have improved significantly, but the concept is still much as it was. Today bag filters are made in hundreds of configurations, sizes, and shapes. Bag filters are usually found in larger collectors or Baghouses instead of cartridge filters due to the higher cost of a cartridge filter verses a simple bag. Bag medias can vary from cotton to a P84, or even a pure Teflon bag.

Dust Filter Shop has successfully cleaned almost any type and design of filters over the years. (It is recommended that cotton filters are not cleaned because they will shrink in length just like a pair of blue jeans.)

Feasibility of cleaning a filter depends on the size and media. Most filters are a good candidate for the cleaning process. The process of cleaning filter bags has not changed much over the years. They are basically washed in large machines designed to remove large amounts of dirt and dust. We clean many styles of filters including:

- Pulse Jet Filter Bags

- Reverse Air filters

- Shaker Bag Filters

- Envelope Filters (DCE – Volkes)

- Multi Pocket Filters

What sets Dust Filter Shop apart?

Methodology

We don’t simply use one soap, or one program. DFS has an engineer on site to evaluate and develop a “SOP” for each filter sent in for cleaning.

SOP’s are developed by our team for each order, taking into account:

- Media Type

- MSDS concerns

- Safety procedures

- Waste handling

- Type of dust or dirt

- Physical size, and batch size

- Correct method, and program

- Best solutions

The staff develops a cleaning plan, and the correct solutions. Plans are documented and the process recorded. The next time the same filter comes in for cleaning, the same method and solutions are used on each and every filter so results are consistent.

Testing

Incoming filters are tested to provide a “Dirty Filter” baseline. Upon completion of our cleaning process the filters go through rigorous testing and quality control checks verifying:

- Media condition

- Seam wear

- Holes

- Correct size

- Permeability (air flow)

- Weight (dirty vs. clean)

In case there is ever a question a “Technician’s Data Report” is maintained for each order. Records are maintained for a period of 7 years.

Rejects

Filters outside specs will cause the filter to be rejected. Upon completion you will be notified as to the number of rejects, and given the option of replacing the filter with a new one.

What used to be a haphazard method is now more scientific, and advanced. DFS is the only filter cleaner that uses this engineering, or scientific method to get outstanding results.

Why not work with the best!

www.DustFilterShop.com

Dust Filter Shop, 811 Main Street POB 266, East Lynne MO 64743

Copyright 2019-2020